Chapter 5 - Presentation of the research field and justification of case studies

In this chapter, we start by presenting the aviation industry market and specially the context of equipment manufacturers with current challenges for this ecosystem (see section) We insist through its history the nature of constraints, their formalization and how the industry professionalized over time.

Then, we continue by introducing our research ground and the specificity of Zodiac Aerospace and how relevant it is for our research questions (see chapter 3). The organization structure of this conglomerate of SMEs and history of acquisitions is described in order to provide enough context for the reader to grasp engineering and marketing challenges.

Finally, we will briefly present the selected cases (see section) before diving into the analysis in the following parts 3, 4 and 5. We explain the contribution of each case to our research methodology and to article writing.

Aviation industry market

The aviation industry started off with many successful and failed attempts since the eighteenth century. It is only after the 19th century industrial revolutions that investors and influencers started promoting the development air balloons, Zeppelins and gliders along with engine-powered aircrafts.

In this section, we develop the establishment and evolution of this market, the challenges associated with product development, its perspectives, and the position of a large equipment manufacturer such as Zodiac Aerospace.

Sources used for this section range for courses taken by the researcher during his studies in aeronautical engineering (ISAE-SUPAERO), the Museum of Conservatoire National des Arts-et-Métiers, public domain documentation (Airbus/Boeing market forecasts and EASA/FAA documents) and internal documentation provided by the communication office of Zodiac Aerospace.

A global sector for an increasing traffic

Pioneering, establishment and consolidation

It is usually recognized that the first flight of a fixed-wing powered-aircraft was the Éole in 1890, developed by Clément Ader with the support of the Péreire family - who had previously financed part of Hausman’s renovation. His works were an application of discoveries and theoretical models formulated earlier in the century by George Cayley (first fixed-wing glider and formulation of drag and lift forces and the usefulness of cambered wings1).

The French Military Ministry had gained interest in his engineering efforts who encouraged further experimentation with the support of the ministry’s engineering departments, a council of professors and the establishment of a school of “aircraftery"2. The subsequent developments led to Avion II and Avion III (see Fig.1), the army had plans for observation and bombing. Several experiments were conducted to master the aircraft. However, with the crash of Avion III, the difficulties to explain what lessons could be drawn, and the secrecy imposed by the Army, left C.Ader without any further financial support to continue the trial-and-error process started. As explained by himself in his book (Ader 1907), he may have started too early and it would have been preferable to work publicly. It then abandoned the legacy of the Éole and his larger project of contributing to the National Defence through the founding of a school for aviation.

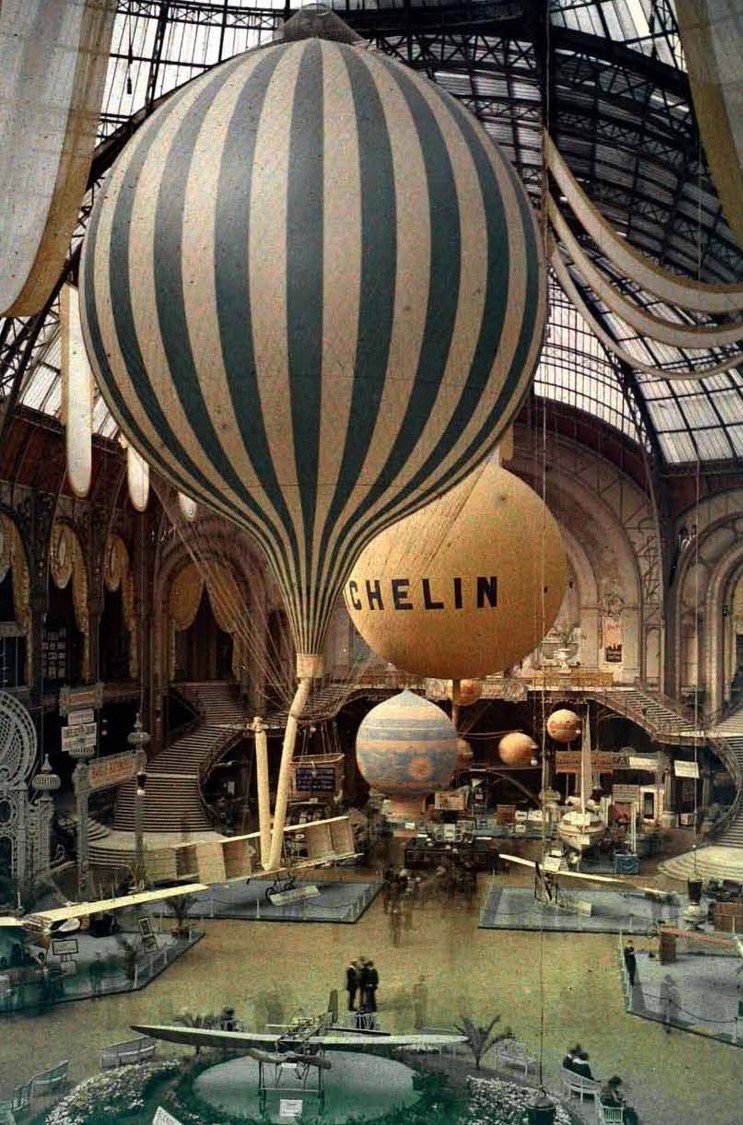

Clément Ader’s project would be fulfilled later by Colonel Jean-Baptiste Roche when creating the Superior School of Aeronautics and Mechanical Construction in 1909, now known under the name of ISAE-SUPAERO (Toulouse)3. But another trend had gained more visibility in parallel to development attempts of rotating/fixed-wing aircrafts: hot air balloons had been developed starting in 1784 with the Intrépide flying over the Versailles castle with Montgolfier brothers4. Several “research companies” (Société d’Études) were established to develop airships with the support of investors (a key venture capitalist at that time was Henri Deutsch de la Meurthe), politicians, and academics from different institutions (Aéro-club de France, Science Academy, Engineering Schools such as Mines ParisTech, Ecole Polytechnique and St Cyr). For example, here are a few key names: Grands Ateliers Aérostatiques du Champ-de-Mars by E.Surcouf in 1880, later renamed Société Astra who would manufacture Wright brothers’ aircraft under licence and Société “Mallet, Mélandri et de Pitray” in 1896 (later named Zodiac in 1911)5. They had an industrial vision for these applications that were the hype in that time in World Exhibitions. Along with air races and numerous experiments, applications for the Army and Transportation were also targeted as use cases. They had been validated for instance during the American Civil War with the Union Army Balloon Corps6.

Besides airships, technology transfers and alternative approaches where developed during the same period such as the effort of Alberto Santos-Dumont with the famous 14bis (1906) and Demoiselle (1907) fixed-wing aircrafts, Henry Fabre (first seaplane in 1910) and Coanda’s first alleged jet engines (ducted air fan with combustion chamber in 1910), Appareils d’Aviation Les Frères Voisin (est. 1906, later split and integrated into what would become Gnome&Rhône est. 1905, i.e. SNECMA/Safran Aircraft Engines) and Blériot Aéronautique, a constituent of today’s Airbus along with former Dassault Aviation (Société des Avions Marcel Bloch, est. 1929) who had merged with pioneering work of Bréguet Aviation (est. 1911).

Of course, the list is not exhaustive, but we would like to stress the numerous links tied by inventors and investors across several decades of experiments, partnerships and industrial settings. And similar stories could also be presented in other countries of Europe and North America.

The frenzy was also channelled by the founding of companies such as Compagnie générale transaérienne (est.1908 by Blériot) Compagnie des Messagers Aériens (founded in 1919 by Bréguet, Blériot, Renault and Caudron) and Compagnie Générale Aéropostale (est. 1918, by Pierre-Georges Latécoère) who created a market to sustain an emerging industry besides military applications. The former would then be acquired by growing competition, mergers to become Air France for instance.

The premises of the aviation industry was a collective effort of engineering where a dominant design was gradually established discarding airships for reliability issues. Different architectures with engines moving from the back (pusher) to the front of the fuselage (tractor), different profiles for lift and drag trade-offs (“canard configuration”, box-kite) and steering/stability equipment (box-kite, dihedral, rudders, ailerons), fixed wheels or idlers, etc.

A turning point: jet age

Following major improvements made during and after World War I (WWI), the jet era would finally come to existence despite first tentative steps made by Henri-Marie Coanda in 1910. The latter being marginalized during the second exhibition of the International Aeronautic Salon in October 1910 against standard designs and persisting doubts/controversies on the actual airworthiness of the aircraft and the engine (ducted air fan or actual jet engine). The figures below show the Coanda-1910 ([sub:Coanda1910]) versus the two dominant designs of that time: airships and unshrouded propellers aircrafts ([sub:Salon1909] and [sub:Salon1910]).

As several records would be broken by aviators (distance, time and speed), aircraft designers and manufacturers would also compete in engineering novel engines, optimising propellers, materials, in addition to wing and fuselage designs. For instance, one can recall the success of Blériot XI when crossing the English Channel against Antoinette aircraft, encouraging its promotion during the 1st Paris Air show (see Fig. [sub:Salon1909]).

Conceptual models and theoretical efforts were made by physicists and engineers building upon the earlier works of George Cayley in the 19th century. Besides the need for pilot training such as rudimentary “tonneau Antoinette", wind tunnels were built to formalize design parameters in addition to testing facilities sponsored by the army. For example, Gustave Eiffel wind tunnels built in 1909 in Paris (Champ de Mars) (Gallant 2002; Barr 1992) contributed not only to mechanical engineering for buildings but also to aerodynamics.

Air Transportation would only start to exist with several routes of airships in North America and Europe, but with WWI bombers converted for passengers, the first airlines were created and dedicated aircraft designs such as the Farman Goliath F60 derived from the F50 bomber (see Fig. 3). With increasing speeds, optimization of turbo-propellers, sonic speeds can be reached at the propellers tips, so shrouded configurations can be beneficial encouraging the development of ducted-fan and then turbofan, a kind of jet engine.

Advancements in jet engines became a major architectural innovation for heavier-than-air aircrafts (Henderson and Clark 1990). It sets a milestone in the development of long haul flights and commercial aviation. It would be hard to say that it was unexpected for established industrial players. However, it raises the issue of perception and cognition of change in product design (incremental, radical, architectural and modular) and the ecosystem deals with the emergence of this shifts.

The onset of the jet era occurred with the commercial aviation intensification, flight routes tailored supporting a wider phenomenon usually dubbed “globalization”. Distances are shortened, leisure is democratized for wider categories of population, with major emphasis put on the efficiency of engines for airlines operations.

The frequency and variety of aircraft missions across the globe also raised numerous evolutions for safety and robustness. Redundancy is the baseline for most aircraft systems (operational). Several other architectural innovations can be listed in the evolution such as the elimination of the Flight Engineer in the cockpit as a side-effect of development of electronics and digital commands.

Market order and segmentation

Major players and market organization

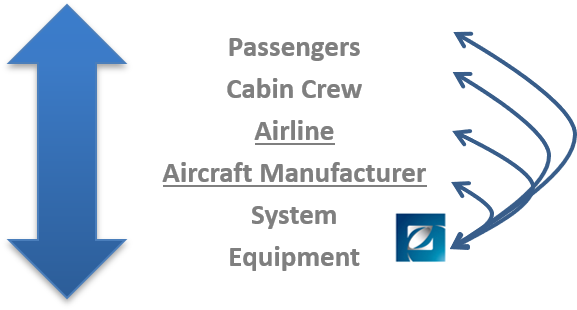

The market is mainly organized by aircraft manufacturers who integrate the systems and equipment (co-)designed by suppliers. It is hardly impossible to avoid the prescription mechanisms associated to Boeing and Airbus, and marginally by Bombardier, Embraer and increasingly Irkut and Comac. Several mergers of engineering services and manufacturers consolidated what Boeing and Airbus are today. For instance, Boeing absorbed McDonnell Douglas, Airbus is the result of the merger of Sud Aviation and Nord Aviation to become first Aérospatiale. Forces were joined, redistributing the roles of among historic roles: airframers, structural part engineering and aircraft integration.

Overall, the market can be seen as an oligopoly for systems and equipment manufacturers. The whole being layered to meet the integration requirements of the aircraft manufacturer. See Fig. 4 for further details.

After numerous series of mergers and acquisitions at all market levels, the number of players has reduced drastically. This consolidation has put a certain order and hierarchy in market relationships, encouraging players to by-pass some players to gain insight.

One can refer for instance to the mapping built by Grundman Advisory from 1993 to 2016. A few more can be added such as Safran acquiring Zodiac Aerospace and United Technologies Corporation (UTC) with Rockwell Collins (who recently acquired B/E Aerospace). The very large mapping (pdf format) can be accessed on Grundman’s Advisory news section: Aviation Week publishes Grundman Opinion, “A map of aerospace mergers and acquisitions”7.

Given this context, airlines undergoing changes in demographics, population displacement, market design (e.g. hub structure) have evolving requirements for aircraft missions: longer routes, multiple stopovers across a continent, low maintenance etc. The aircraft manufactures perform a preliminary proposal to meet their key customers (major airlines).

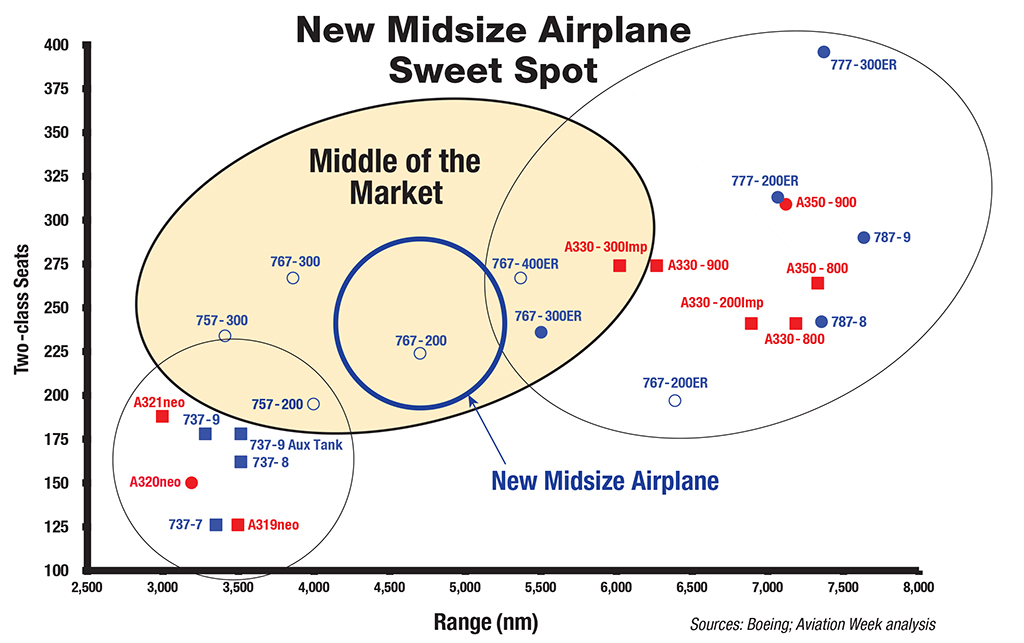

Aircrafts can be categorized in now three groups: short/long haul, and currently business magazines tend to introduce the concept of “middle-of-market”. Below, Fig. 5 shows along two performance criteria the three sets of aircrafts. Despite visual and alleged similarities between short/long haul aircrafts, physics, design rules and systems’ architectures do not allow a simple rule of three. Aircraft programs are spanned across roughly a decade in average (from the early designs to first delivery) mobilizing several suppliers in a co-development process and requirements cascaded down along the hierarchy of product/service design.

Among suppliers, as most players are conglomerate of SMEs, these follow in broad strokes the perimeters given by the ATA chapters (Air Transportation Association). The classification is originally intended for engineers and technicians performing repairs and maintenance duties on aircrafts. Aircraft systems are covered from ATA no.20 to 92. For example, ATA 44 corresponds to Cabin Systems, where one can find the following sub-systems:

-

44-00 General

-

44-10 Cabin Core System

-

44-20 In-flight Entertainment System

-

44-30 External Communication System

-

44-40 Cabin Mass Memory System

-

44-50 Cabin Monitoring System

-

44-60 Miscellaneous Cabin System

As one can see, it does not cover for instance several “monuments” found in the cabin: seats, class dividers, lavatories, galleys, etc. ATA follows a system architecture description and the cabin domain should be seen as an area sanctuarised by airline for customization and branding. Naturally, it has more players specialized equipment certified by Technical Standard Order (TSO, see below for further details).

Importance of safety and regulations

First safety regulation can be associated with a publication of the Paris Police headquarters dating from April 23, 1784. It followed the flight of the hot air balloon built by the Montgolfier brothers in late 1783 for King Louis XVI at Versailles castle:

It shall be unlawful to manufacture and lift off balloons and other aerostatic machines with heaters using wine spirit, fire crackers and other flammable materials and orders that all other aerostatic balloons may not take-off without permission. Such permission shall only be granted to people with recognized experience and capability…

From the early delays, the approach to aircraft safety came as insurance for justifying on one hand what objects were safe and reliable according to a set of standardized criteria and on the other hand the how and the who required to design, develop and sustain these objects.

Despite some differences between the rules established for North America and Europe - Federal Aviation Administration (FAA) and European Aviation Safety Agency (EASA) respectively - they ensure airworthiness8 along four main domains:

-

Monitoring Safety issues

-

Product Certified & Checked

-

Safety Rules & regulations

-

Approved Organizations

These topics are declined in the certification process that is recognized with the issue of Type Certificate for the aircraft and associated scope covering critical systems and equipment (e.g. electrical power generation and distribution). In addition, almost standalone equipment such as engine have their own Type Certificate and “less critical"9 equipment with Technical Standard Order (TSO); so they can be qualified and certified with a relative independence from the aircraft manufacturer.

The general process is described in the Fig. 6 pictures the phases until the release of a form (e.g. EASA Form-1/FAA 8130-3) validating the conformity of the manufactured/repaired product given an extensive list of justification documents issued by Design, Manufacturing and Maintenance activities. The figure also insists on the fact that airworthiness is maintained throughout the life of the product, meaning until it is dismantled and removed from the aircraft fleet.

The certification and crucial airworthiness aspect, a more technical set of requirements are addressed by system/equipment/technology/material-specific standards. These are issued by several regulatory bodies such as SAE International (Society of Automotive Engineers) issuing Aerospace Recommended Practice (ARP), EUROCAE (European Organization for Civil Aviation Equipment), RTCA (Radio Technical Commission for Aeronautics) issuing standards for instance “Environmental Conditions and Test Procedures for Airborne Equipment”, MIL-STD from the US Military Standard, etc. Qualification and design processes requirements are largely compliant with these standards in addition to customer requirements.

Last but not least, the International Organization for Standardization (ISO) has greatly contributed to the standardization of processes with ISO9100 / AS9100 (Aerospace Basic Quality System Standard).

Challenges and future changes

The market is rapidly growing based on surveys and forecasts made by Boeing and Airbus on yearly basis. Asia-Pacific countries are greatly contributing to this trend with legacy aircrafts being retrofitted in major American and European countries despite several external shocks.

35000 aircrafts will be delivered by 2036, among which 13000 are for replacement and the rest being actual new deliveries growth. Traffic will keep on increasing with rate per annum from 2.5% between advanced countries up to 6.2% between emergent countries taking most of the traffic share (40%). Finally, several other trends can be foreseen with environmental considerations, passengers demographics and changing urban mobility.

Greener aircrafts

The rising awareness of human’s activity on Earth has also encouraged the aviation industry to develop means of reducing its greenhouse effect share. For instance, from the viewpoint of fuel combustion, optimizing engines with a criteria such as number of passengers per kilometre per litre of kerosene in addition to emitted $CO_2$ and $NOx$ particles per number of passengers per kilometre. Tremendous engineering efforts were made to enhance the efficiency of the combustion chambers, engine sections (fan, compressor and turbines) and overall architecture (by-pass). These efforts are still on going with open-rotor engine. Taxiing of aircrafts could also be changed to avoid burning fuel with electrical drive in landing gears or pushback car integrated on taxiing rails.

Other architectures such as delta wing for commercial aircrafts and V-formation flight (inspired by geese flying patterns) have been imagined by industrial actors. These approaches also tend to think the overall aircraft and its integration within the airspace and airports. Incremental innovations however can be designed by using lighter materials while guaranteeing strength. For instance, marginal improvements on wingtips or using composite materials for the skin of wings and fuselage reduce overall weight. Nevertheless, these replacement are not modular as it dramatically reduces the electromagnetic shielding required against thunderstorms or simple electromagnetic interferences. Shielding should then be improved across wirings and harnesses needed for fly-by-wire systems10 and several other electricity powered devices.

A greener aircraft does not only imply optimization along several green-performance-indicators exploiting the dominant design, nor replacing some features, but also has a greater impact on the architecture of the aircraft itself and sensitivity to the evolutions of the aircraft integration (e.g. airport, air traffic patterns, flight route demands, etc.)

Passenger demographics and trends

Passengers through airlines interaction the evolution of the market. Passengers are more and more observed and consulted by airlines, aircraft manufacturers and equipment manufacturers. Beyond traditional satisfaction survey, creativity sessions and ethnographic observations in “labs”11.

Currently, the expectation of passengers are changing. Let us take, for instance, the evolution of seats in the cabin. Historically, no distinction existed. Then with the gradual democratization, class segments were created: first, club and economy. The club disappeared to be replaced by the idea of a business class, with now sometimes dense business class, reducing the size of the first that aims for a hotel-like experience. These nuances should also be declined depending on culture and flight routes across the globe.

Ageing population is another concern for cabin layout including: seating and lavatories. Reduced mobility of certain categories of passengers also causes several issues for seating, movement along corridors and reaching for different cabin areas. Seats architecture and access are modified, additional equipment to assist are also designed.

So called millenials emphasize the rising ubiquity of (Internet) connectivity on mainland and ground transportation. Airlines have been gradually shaping the business model of connectivity with new suppliers and services providers offering solutions guaranteeing an almost continuous connectivity. From traditional shared displays hanging over seats, to seat-centric inflight-entertainment, the passengers are now also willing to connect to existing solutions: in-flight connectivity (Wi-Fi and entertainment server) supported by antennae and ground/space relays, and active/passive displays for mirror casting personal device content or accessing airline provided content.

These novelties being transferred from an evolving society and use cases where aircraft experience may appear old fashioned. They bring numerous uncertainties to a professionalized and highly constrained engineering. New product development may then fit the given architecture but may also encourage the generation of ad-hoc solutions and reconfiguration of (epistemic) interdependencies.

Urban mobility

Finally, another major trend is the regain in urban mobility. The reducing flight times and connecting time at stopovers, has dramatically reduced distances across the globe. Combining this trend with city expansion, road and general public transportation can become saturated to point where other means must be developed. In cities of high inequalities such as Sao Paulo, helicopters are an efficient alternative to travel across the city avoid traffic jams for those who can afford. Social imaginaries tend to contribute to urban mobility effort on adapting aircraft to fly safely through the city skies. Science fiction works in literature and movies have embodied these ideas for more than a century.

However, it is gradually becoming a reality with Unmanned Aerial Vehicle’s technologies developed in the past two decades. Automation, algorithmic robustness, and mastering of flight dynamics for quadcopter designs for instance were key in addressing the scaling of remote control devices to civil/military applications, and up to autonomous taxi.

In the last 5 years, several initiatives, usually referred as Passenger Drones, were launched. In China, eHang 184 flew early 2018, in Germany, Lilium is being developed, in Dubai and Germany the Volocopter was developed and test flights were conducted, Airbus has two concepts developed in two different centres: a traditional vertical-take-off and landing (VTOL) called Vahana, and a modular solution combined with car Pop.Up. These passenger drones enable on-demand air transportation expanding the horizons of taxi fleets and personal/public transportation with safer means of flight travel that are not reachable with traditional light aviation airworthiness.

The evolution of the market order and segmentation given the highlighted trends encourage equipment manufacturers to carefully reconsider the way products and services are developed. In the following section, we develop how projects and programs are managed given the aviation history depicted previously. Its professionalization has established rules, processes and structures to support new product development which we will address at the light of several novelties, increasing uncertainties and the need to innovate, i.e. managing the unknown.

Zodiac Aerospace Innovation Context

In this section, we propose to present the context of the research project offered by Zodiac Aerospace. We cover its overall organization, its history, examples of major innovations in the aviation industry and how R&T and Innovation are managed across the group of SMEs.

General organization: conglomerate of SMEs

The thesis was conducted at the Technical & Innovation Direction of Zodiac Aerospace (ZSA, holding). Established in 1896 by Maurice Mallet, the venture initially targeted airship and fabric engineering. It has now turned into a large industrial group of 75 entities designing, developing and manufacturing aeronautical equipment for aircraft/helicopters manufacturer and airlines. These are located over 100 facilities across the globe and mainly centralized in Europe and North America. In the last couple of decades, some facilities were established in cost-competitive countries for the serial production of some entities.

The group of SMEs where each of them, with a few hundreds employees each, equating to a total of 35,000, have their own responsibility and performance logic. A light group holding of 200 employees with several support functions have the challenge to manage the sometimes competing SMEs due to the market structures and build up synergies targeted by the executive committee. As shown in the following page, we present the variety of Zodiac Aerospace products that can be found on an aircraft. The segmentation by branches dates from 2015, but the current status is a merge between Cabin & Structures and Galleys & Equipment (now called Zodiac Cabin), and Aircraft Systems and Aerosafety (now called Zodiac Aerosystems). Most equipment is represented by a single business unit, overlap is rare between entities. For example, in the kitchen area (galley) the configuration is the following with all separate engineering departments, standards and regulations and sales channels:

-

The galley structure (frame, panels and fixtures) is developed by Zodiac Galleys Europe/US

-

The inserts (oven, boilers, coffee makers, bun warmers and ice containers) are developed by Zodiac Electrical Inserts Europe/US

-

The trolleys designed by Zodiac Air Catering Equipment

-

The lavatories are composed of the lining/decorative elements (Zodiac Airline Interior Integration) and of toilet seat and underlying water & waste systems (Zodiac Water & Waste Systems)

A history of complementary niche strategy

Zodiac Aerospace, actually stems from the separation with Zodiac Marine. The former Zodiac Group had been expanding between seas and skies with technology transfers from air balloons to inflatable boat12, and several other extensions playing on complementarities to expand its footprint.

The history of mergers and acquisitions, leaving aside the former Zodiac Marine group of entities, can be traced back to the seventies with EFA (Parachutes in United States) reopening the aeronautics branch as shown in the figure below (Fig. 8). The main drivers for acquisitions, as explained on Zodiac Aerospace corporate presentation, are synthesized into five key principles:

-

Diversifying in businesses with a high technological content, through internal and external growth

-

Favouring niche markets to rapidly attain leader positions

-

Ensuring steady growth in earnings per share

-

Supporting customers over the long-term through a strong after-sales activity

-

Aligning our operations with the Principles of the Global Compact

The first group of acquisitions intended to gain stronghold in the aircraft safety systems market whilst still developing some related marine activities around rubber coated fabrics (Kléber Industries), flexible tanks (Superflexit), parachutes (EFA, Parachutes de France) and arresting/evacuation systems (Air Cruisers, Aerazur). The family shareholders’ trust put in the newly appointed CEO Jean-Louis Gérondeau. He led an external growth strategy helping the financial recovery and building a strong position in the aircraft equipment market. The strategy was then extended with several other niche markets (mainly oligopoly) with high added value justified by complex engineering know-how complying with safety and airworthiness regulations. For instance, early nineties was the entry into the aircraft seating (Weber Aircraft, Sicma Aero Seat), water & waste systems (Monogram/MAG Aero and Avon) and oxygen devices as well as sensing and systems management (Groupe Intertechnique).

Overall, we have more than 40 acquisitions since late seventies which enabled diversification around the inflatable boat decaying market with sport and leisure perspectives. But mostly, the group regained a leadership position in the aircraft equipment market by federating numerous SMEs.

As told by Olivier Zarrouati13 during an open interview in May 2018 conducted by the PhD candidate:

We scouted our environment for niches with high added value, after a selection process, we would then make sure that new business unit will be able to perform and hold its position in the market. When it comes then to innovative concepts, the trick is really to make sure they understand the value of novelty on their own and not by forcing it by top management.

This mindset was also confirmed by a separate interview made with the Vice President of the group, Maurice Pinault, former CEO of Zodiac Marine activities.

Feats of engineering

The history of Zodiac Aerospace has left several landmarks in the domain of engineering. Starting the nascent airship venture, engineering know-how was developed for fabric engineering and sewing techniques. Then, when redeveloping the company in the aircraft market over less than three decades, the group developed its competencies in complex engineering for aircraft systems, and material and stress engineering for cabin equipment.

Technical fabric and associated technologies

The airship industry at the wake of the $20^{th}$ century required not only building an understanding of models of flight mechanics but being able to design, engineering and manufacture robust fabric assemblies. Standards of quality or test engineering were being gradually established. Tensile strength of a piece of a fabric was crucial but sewing techniques was an even more critical feature of these assemblies. Advanced Sewing techniques were required for overall resistance to aerodynamic forces (lift and drag) and associated designs.

With growing competition in an established market of inflatable boat, Zodiac Aerospace managed to expand these competencies with the parachute industry, inflatable boats, airbags, emergency evacuation systems (slides, life rafts) and arresting systems (nets and harnesses on runways). Several of these high skilled work can also be observed in weaving and braiding techniques for conduits and hoses for harsh environments. The developed industry thus greatly differs from clothing industry with safety and airworthiness standards that imply a wide spectrum of physical variables (temperature, tensile in static/dynamic modes). It has greatly contributed to the unique position in a quasi-duopoly with strong commercial and technical bonds with aircraft manufacturers (Airbus, Boeing and McDonnell Douglas).

Zodiac Aerospace has dominated the market of Parachutes, aircraft arresting and evacuation systems and also part of the market associated with braided/woven products. Unique technologies were developed to remain competitive in several areas: flexible fuel tanks, open sleeves for electrical harnesses and net arresting systems.

Composites materials and cabin equipment

Early nineties, the Zodiac group had been developing the leisure and sport marine domain to expand the inflatable boat market (Zodiac, Avon and Bombard product lines). Their entry into the aircraft seating market was done through Weber company who also had several engineering and manufacturing capabilities in aircraft parts and synergies with its former conglomerate Walter Kidde and Company Inc who had sold the business to a largely diversified British conglomerate (Hanson PLC).14 Kidde had also a foot in the inflatable boat market during the war effort. A similar move was operated with SICMA in France, which had been developing aircraft structural part, seats and also skis and tennis rackets.

Engineering could be then developed in the domain of material engineering. Structural parts for pilot, crew and passenger seating were developed and kept leadership by meeting and developing further safety and certification requirements with authorities. The rest of the cabin would then require similar technical capabilities for stress and flammability constraints.

All cabin interiors and galley’s area require qualification and certification competencies to package for instance kitchen appliances to airworthiness standards. All of which also requires to withstand severe static and dynamic mechanical testing which are complex to monitor and use for further design of assemblies and parts. Furthermore, standardization is not common in this market because of market volumes and changing demand of airlines looking for unique branding opportunities.

Aircraft systems

At the end of the $20^{th}$ century, the group continued to settle its position in other fields of the aircraft equipment market. Monogram (MAG Aerospace) and Groupe Intertechnique were acquired. They had respectively developed themselves in the field of water & waste systems engineering and embedded systems for aircraft operations (computer, printed circuit boards, fuel gauging systems, oxygen masks and control systems). These two first acquisitions were a key advantage to secure market niches. Added value is accomplished through complex system engineering, functional robustness and secured certification capabilities for further product development. It was the occasion to combine engineering competencies into the creation of a business unit in the field of airbags for automotive industry with inflatable technical fabric and precise control electronic systems.

Later, these activities would be complemented by several power electronics generation and distribution (ECE, Zodiac Electrical Power Systems), wiring parts/systems and hydraulic, servo-control and ducting systems. The underlying SMEs acquired on such domains had been building their field first through components and quickly grew into engineering of sub-systems and full systems in order to cover regulation and certification domain. Several breakthroughs can be mentioned such as inerting systems for fuel tanks, oxygen regulators, or even metal fabrication in harsh environments.

Today’s R&T and Innovation: an oddity for innovation management?

ZSTC and Experts Network

Established in 2010 by the managing director of former Intertechnique group (covering former Aerotechnique group of activities, i.e. Fuel & Control Systems and Oxygen Systems), the Zodiac Scientific and Technical Council (ZSTC) gathers engineering managers and R&T managers equally representing the variety of activities in the group. It was created for four main objectives:

-

Prepare technological evolution for the decade ahead and reinforce synergies: long-term Technology Road Map were created to fit market & sales perspectives to feed product lines.

-

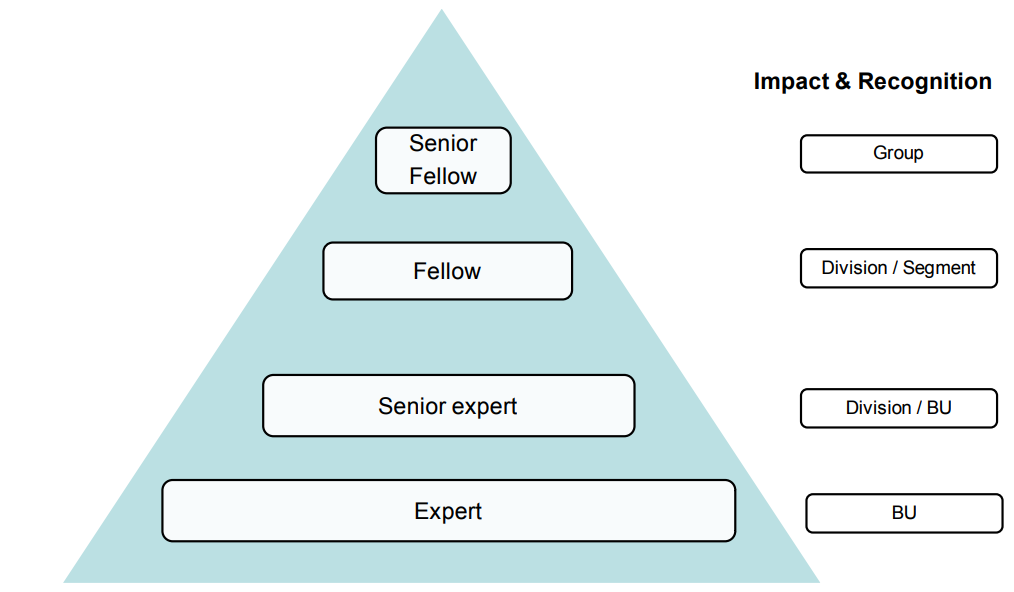

Value technical experts across the company: expert career path created with Human Resources for engineers preferring a technical career instead of one dedicated to management15.

-

Reinforce relationships with academia, start-ups, innovative suppliers and potential partners: incentives to host PhD candidates in R&T departments, collaborative research programs, TechnoDays seminars to gather people around common topics (e.g. composite materials, electronics, systems engineering, etc.).

-

Reinforce Intellectual Property protection and management, as well as R&T management practice (guidelines and procedures)

The council creation was supported by the Vice President of the group (Maurice Pinault) for its strategic leverage:

It is a major leverage of growth for the Group such ours which designs and manufacturers the most complex systems and that is required to meet regulation constraints and quality & safety requirements increasingly harder. In 2010, we created the ZSTC to improve the performance of our technological research, to gather necessary resources for our competitivity and foster the development of cross-cutting innovation with high added value.16

The joint effort contributed to encourage transversality through some major disciplines for the group such as material flammability, power electronics, systems engineering and composite material engineering and manufacturing. TechnoDays have been organized for these topics, experts were nominated locally in business units, and through round of interviews experts gain different status degrees of the career path:

Late Creation of R&T function through TRL assessment

Given this initial background and internal efforts made in the business units Zodiac Fuel & Control Systems to constitute a dedicated R&T Team (in 2012-2013), workshops were organized with the support of a consultancy firm to define and implement technology road maps (TRMs) for all business units. With a bottom-up approach validated by top management strategy, road maps were fed with marketing and sales data picturing the future markets and technologies were identified to enable and facilitate potential market access. Aircraft and equipment manufacturers had been implementing the notion of Technology Readiness Level (TRL) which streamlined the road-mapping.

Guidelines were subsequently written to support the rollout of this new language and practice. Business units were then able to provide and use a maturity assessment canvas for the technologies in development and the road ahead for integration. The president of the ZSTC was then appointed Chief Technical Officer (CTO) of the Zodiac Aerospace group, a new position created by the CEO. His role consisted in gradually institutionalizing the R&T function in business units, supporting them for public funding opportunities and auditing the practice of R&T and innovation management (TRL assessment, TRM, patent application and PhD subjects).

An innovation locus where exploration project management and organizational design clash

So far, we have portrayed in the previous pages the history of aircraft engineering, the establishment of design rules and the acquisitions strategy of Zodiac Aerospace. Several key features can be listed characterizing the innovation context for Zodiac Aerospace (see below).

-

An industrial ecosystem at stake with increasing uncertainties and unknown due to strong segregated rigidities mirrored by engineering, safety and regulations but facing potential radical transformations of architecture

-

Complexity and difficulty to master a full system (architecture and components) - myopic behaviours

-

Architectures defined in a contingent manner by the ecosystem raising uncertainties and the unknown shifts

-

Urge to innovate for strategic competitive advantage in the wake of a radical change

-

A consolidated market made of conglomerate but without being traditional divisional firms

-

Autonomy and responsibility of individual SMEs but the necessity to orchestrate their interdependencies to innovate

-

Projects situated in a intra-BU and inter-BU context challenging product/service design and organizations simultaneously

-

A light corporate team dedicated to innovation with several relay networks (professions, experts)

Zodiac Aerospace presents a distributed innovation management with an ongoing standardization for processes (Quality Management System) and to some extent structures (R&T department separated from Development Engineering). Each BU has its own responsibility and dedicated financial reporting. They all face their own market segment with the associated professionalisation but also the urge to embrace uncertainties and the unknown to innovate.

This situation encourages to understand the place in the (aircraft) system architecture, the interfaces, the interdependencies and knowledge yet to be discovered to guide exploration and consider synergies with other BUs. It is a concern for top management as they worry about the strategy of this portfolio of SMEs.

The CEO and VP17 have stressed the idea the intent was to secure the niches in the long run, but still develop their own capabilities to prepare the future. They specified the importance of branch directors to oversee the portfolio of business units to build a sustainable strategy for them. Top management had for instance launched several initiatives they considered to be key for the group or gave a place for bottom-up projects.

For example, transversality was gradually being organized with communities of experts, TechnoDays, (in)formal communities of practice for engineering and R&T managers at the BU or division level. Top management also decided to launch projects and places were novel products and services could be developed in-between the organizational boundaries or just seen as strategic for the whole group. A fuel-cell project was launched, hosted by a business unit with the prospect to developing this technology for the aircraft equipment market with perspectives on electricity, water and heat management. Two teams were set near aircraft manufactures: one near Airbus and the other by Boeing. These teams were composed of several engineers, designers and managers from different business units. They dedicated 50% of their time to technical support for their BU of origin; the rest was dedicated to business intelligence and innovation management. Workshops, prototyping, and presentations were regularly organized by the team to generate concepts sometimes in partnership with clients, users and also representatives of BUs.

The gradual rationalization of the R&T and Innovation activities since 2010 with the establishment of R&T and Innovation management within each BU was supplemented by an effort coordinated by top management to the develop even more radical design of products and services. The former tend to address incremental innovation, sometimes radical ones aimed through a path punctuated by several steps to test their environment. For instance, long term projects are part of partnership agreement funded by institutions such as associative, national or international Research Councils. The latter were a means for the Executive Committee to protect existing niches from more radical concepts.

In these specific case raising strategic interest, such project were addressed in a different locus breaking away from the existing and protected organization design: the multi-BU committee was rather convenient. Otherwise, the Business Unit being is considered as an indivisible unit. It encourages the development of alternative approaches: fostering exploration topics, steering committees for valuation and strategy, and project management.

Case studies selection

Brief case description

Below, we present the different case studies conducted at Zodiac Aerospace and that where discussed in five different articles in Appendix. Due to organizational dimension of innovation management of this conglomerate of SMEs, and the organization design, we propose to split the cases in two categories: intra-BU and inter-BU. The trajectory of studied projects were, in fact, more or less contained within the perimeter of a business unit, market segment, qualification/certification requirements. Other cases were deliberately set in between these boundaries or across with top management sponsorship.

Intra-BU cases

Icing conditions detection

The first impulse originated in the early 90s with the concern a former CEO - Intertechnique group (now Zodiac Fuel and Control Systems) - and with the crash of an ATR72 in the U.S.A due to ice accretion on wings. A project manager and engineer (who would eventually become the R&T manager), developed an ultrasonic sensor for wing’s skin to detect ice and measure icing-protection fluid dilution ratio. It allowed participating to several test campaigns, to gain a reputation in the field for safety and airworthiness (DGAC, EASA, Transport Canada), and develop two versions of the technology with the support of funding (SPAé, European Power Optimized Aircraft) and synergies with pending product development (e.g. computer electronics for A380). A first patent was applied.

Early 2000s, the technology is compared in test campaigns with the monopoly’s solution (Goodrich, former Richmond; mechanical oscillator). It proved its efficiency on the ground but not for flying conditions due to several technical limitations compared to competition’s: no defrost, complex wing installation and high costs. Furthermore, Airbus did not support the development as their aircraft (A380) is not sensitive to icing. Airworthiness institutions were indeed specifying icing conditions types and aircraft sensitivity.

However, regional aircraft manufacturers such as ATR and Bombardier were pushing former Aerazur entity (now Zodiac Elastomer Europe) and Intertechnique for an integrated ice detection and ice protection system. With the support of several engineers recruited in previous years, they developed a solution tested again with the support of Airbus as the icing conditions detection regulations were evolving. Three test campaigns were conducted with convincing results from an alternative technology (thermodynamics and Peltier effect) overcoming the previous limitations.

Despite an aircraft program request for proposal and with uncertainty and potential surprises in airworthiness evolutions, the recently established icing conditions team at Intertechnique pivoted towards an unfamiliar technology for the BU (laser optics). Parallel studies were conducted, and the R&T manager had participated to technology evaluations with FAA and Transport Canada. In addition, strategy and business development managers had considered potential acquisitions to definitely break the monopoly.

Finally, in 2011 a new project on uncertain laser technology was launched within a CleanSky program. And more recently, a second project was launched, with CleanSky2, forking the technology concept developed so far and extending the airworthiness validity domain.

Note: The researcher came around this case with the support of the CTO and R&T manager who explicitly mentioned the need to specify the nature of this projects at odds with other R&T and Engineering Departments activities and with BU management. The project was seen as an unidentified object despite having legitimacy in the airworthiness, safety fields and among aircraft manufacturer engineering departments. The generative processes needed to be further specified to understand the nuances of its innovation potential of attraction with respect to the engineering department, knowledge and organization design.

Business Class Seat platform

This case is an outcome of a recurrent topic at Zodiac Seats France: standardization and modularization of seat architecture to facilitate product development. Indeed, airlines demand for seats change every 5-10 years, including cabin reconfiguration for seasonal passengers flows, and they request a short development cycle of about 2 years, compared to the 10 years (approx.) for an aircraft. However, the seat is absolutely critical in passenger safety with severe qualification and certification requirements in association with increasing demands for airline/passenger customization and ergonomic design. Despite the beneficial prospects of platform engineering for economy and business class seats, the rhythm of product development and complexity in conjunction with optimized resources hadn’t left many opportunities to develop such project.

Separated from development engineers, a recently constituted R&T department was tasked to study the modularization of a business class seat for easier packaging and certification. A large exploration (patent, design options, architectures, technologies etc.) was considered and selection of design concepts were made based on product development criteria and support of several engineering, operations and marketing stakeholders. Further stress simulation and testing was required, but following the bid award from a demanding airline, the subsequent design and development was driven by customer requirements and its design studio.

Several difficulties were discovered late in the development raising questions on the maturity of the design and certification requirements such as increased difficulties associated with the joint qualification of seat and shell and inclusion of airbags. Delays were unfortunately accumulated with numerous quality problems due to technical compromises.

Despite the exploration quality, exploitation issues had to be dealt with. The project trajectory that aimed at developing a business class seat platform was compromised.

Note: The research was introduced to such product development case as he was supporting the R&T department in formalizing the TRL assessment and associated management. The Director of Engineering and R&T managers were intrigued and disturbed by the design choices and integration issues, requesting a deeper understanding of the coordination and collective action model, as well as how the innovation potential of attraction of the platform was managed.

Hypoxia protection - researcher’s intervention

The R&T department was preparing mid-2017 a participation to CleanSky2 program with Airbus as a partner in order to propose new radical solution to protect pilots from hypoxia. The need emerged from the necessity (safety) requiring a pilot to wear the emergency oxygen mask when alone in the cockpit. Such requirement is however hardly compatible with the required comfort of extended use due to emergency design of the mask (high levels of stress, smoke in the cabin, emergency manoeuvre)..

The team was originally constituted of R&T engineers, and then after 6 months, they were stretched over the traditional engineering department dedicated to product development leaving only one R&T member. Numerous brainstorming and design sessions with the support from an external design studio contributed to a wide and in-depth exploration.

In parallel, an internal “Open Innovation Challenge” organized by the ZSTC for which one of the two topics was improving ergonomics of the oxygen crew mask. The researcher had then proposed a C-K mapping to position and value the concepts proposed by ZA participants. In addition to the acquaintance with the R&T and Engineering manager for other purposes, the researcher was requested to support the project team in selecting concepts, and guiding them before the first proposal to the CleanSky2 partners.

It was the occasion to work on the decision-making and the design of alternatives and states of nature, as well as embedding the organization design required to support the innovation effort expected in the project. The dichotomy of exploration/exploitation could then be revisited and nuanced within this project. It enabled the proposal of novel ways to organize collective action within and around the exploration project.

Inter-BU cases

Airbus Development Team - Design Thinking cases

The ADT is sponsored and monitored by the C-suite for strategic management purposes. The team was tasked to provide technical support for several BUs and to generate concepts that would feed on unmet user needs by gaining a better knowledge of real use cases of ZA products. The team is constituted of 8 permanent engineers and designers delegated by BUs for three years maximum, and dedicating half of their time to their BU’s sales/technical support. They report to a local manager who actively contributes to the team creative effort and facilitates discussions with BUs. He reports to the group VP of Strategy and Business Development as well as the Chief Technical Officer.

The Design Thinking (DT) methodology was chosen to promote the user-centric approach, explore usage, share gathered knowledge, and ideate for and with relevant BUs. ADT’s two project leaders were trained to DT at Stanford’s d.school, and other members were trained in other institutions. A design and creativity spirit was largely promoted by the local manager as well as the members themselves. The projects phasing completely covered DT’s enactment themes (Carlgren, Rauth, and Elmquist 2016).

Both cases addressed transverse topics where many BUs are concerned in some way or are actively part of the value chain. The first topic dealt with waste managed onboard aircrafts. The second topic tackled the optimization of aircraft turn around time (i.e. between landing and take-off). Several users and extreme users can be searched and studied to build empathy and also the technical/market knowledge from the different BUs is tightly interfaced around both topics.

In order to fit the scope of work of the ADT, the team shared knowledge with BUs to keep them up-to-date and build legitimacy all along the DT process. A “Multi BU workshop” was organized for problem-reframing and further ideation and prototyping with BUs. A final selection process was defined based on DT criteria and ZA’s strategic intent: customer value, technical feasibility, passenger experience, group strategic alignment, in addition to a separate ranking for “creative sparks”. The selected concepts were then approved by the Group VP of Strategy. Thereafter, they were shared again and promoted to business units who could potentially host their development in their renewed product lines.

Note: the researcher had first visited ADT in Toulouse, since it was recognized as one of the new loci of innovation in ZA. Interested by the PhD project and with several pending problems regarding concept appropriation by BU, the local manager accepted and invited his colleagues to provide relevant project documentation and interviews to gain an understanding of the projects driven by Design Thinking.

Lower deck

As several projects had been launched as well as numerous ideation sessions at ADT, the researcher had presented his analysis of the two Design Thinking cases in March 2016. Among the conclusions, the C-K mapping and project trajectories had revealed the recurrent topic of using the aircraft lower deck (cargo area) as a means to embody several concepts enabling solutions for waste management and aircraft turn around.

The local manager had also a hunch for such topic as it had been quite recurrent in the three years of existence of ADT, including a provisional patent application with a former intern. As the team was about to be renewed, he decided to request the former intern to come back and support a new project dedicated to the lower deck use.

A first market study was launched with a consulting firm to evaluate airline’s ticket yield management in addition to fleet evolution and maintenance dates, to envision the size of lower deck market in addition to its integration. The latter was critical as it implied modifying the aircraft’s cargo area for passengers without disrupting airlines’ operations. The technical feasibility of this retrofit was studied first by an external engineering firm and then deepen by an internal BU dedicated to certifying specific aircraft customization. In parallel, concepts were tested with several airlines’ executives, and the overall business case was discussed with ZA Executive Committee board.

The project proved to be a success as several key client (airlines and Airbus) formalized requests for proposals and project development framing is ongoing (see announcements during last Aircraft Interiors Exposition in Hamburg 2018). Moreover, several BUs are willing to take ownership of the project.

Note: This project has to be read at the light of the Design Thinking projects conducted at ADT and other projects followed by closely by the ExCom.

Connected Cabin

The raising interest for connectivity and Big Data for aviation industry had made its way into Zodiac Aerospace. Such topic was a perfect fit for Zodiac Inflight Innovations who developed inflight entertainment solutions and communication devices as well as Zodiac Data Systems (antennae and inflight test equipment). The topic was rather convenient for another BU such as Zodiac Air Catering Equipment whose market value chain extends from the aircraft galley area to catering services delivering the trolleys to aircraft doors.

Two members of the ZSTC, affiliated to Zodiac Inflight Innovations started pitching the idea in front of the Executive Committee to launch a project on Big Data services centred around an enhanced cabin with connectivity hardware enabling machine to machine communication and management. After two rounds with the support from a member of the ExCom in charge of their business branch, they managed to precise the project scope, potential business case, and needed resource to develop a prototype to probe the market at 2017 Aircraft Interiors Exposition in Hamburg.

A team was constituted with engineers from different BUs providing equipment for the cabin and who had an interest in constituting the connected cabin and developing associated services. The project moved on quickly with bi-weekly reporting meetings followed by the VP of Strategy and Business Development, and numerous side meetings. Moreover, the ExCom made an open statement to investors that a project was being launched to value aircraft connectivity. A cabin prototype was manufactured with built-in connectivity features and scenarized for airlines. It put forward the benefits of retrofitting hardware and software providing value-added services smoothing airline operations and client experience and satisfaction.

The prototype enabled collecting valuable feedback from potential clients and following the exposition the project did not continue.

Note: The researcher came around this case as he knew the two ZSTC members and regularly attended ExCom meetings relative to technology and innovation. They were keen on having him following the progress of the project and keep track of concepts generated along, even before the budgeting agreed by ExCom. This case benefited from the same context and sponsorship as the Lower deck. Consequently, we can contrast them and nuance their respective innovation potential of attraction.

Multi-BU committee

Note: The researcher was regularly invited by the CTO to attend ExCom meetings relative to technology and innovation. These meetings were usually labelled Multi-BU meetings following the interest of former CEO (Olivier Zarrouati) to have a top-down approach urging new projects (such as the Fuel Cell briefly exposed earlier) and also to offer space to projects originating in one or multiple BUs bearing a strategic importance. All of these projects addressed new markets, gaps in between market segments by bringing forward new technologies or new product concepts.

This case is approached not necessarily on the technical, engineering or marketing content of the projects steered by the MBU committee, but rather on the way decision-making was conducted by individuals and teams attending these meetings. ExCom members were all present with leadership from the CEO and VP of Business Development and Strategy. The meetings were prepared by the MBU Director, also called Director of Large Projects (Directeur des Grands Projets) with the support of the Director in charge of product roadmaps. The job involved monthly reporting of the projects to the mentioned VP as they would be subsidized by top management budget (stemming from fees collected by the holding on BUs).

The meetings occurred in average every quarter, sometimes punctuated by other meetings in between for projects requiring an urgent strategic decision: commercial support for business development, group strategy relative to overall market positioning and budget.

The Committee operates as an alternative locus of (radical) innovation compared to in-house R&T and Product Development activities in BUs. It emphasizes the interest of corporate management for entrepreneurship across the group. It also differs from the ZSTC and members of the Innovation Direction whose role leans towards support (processes and tools) and networking for knowledge domains sustained by experts.

Associated paper writing

Anomaly detection - Case studies and written papers

| Paper no. | Associated Paper | Associated cases |

|---|---|---|

| 1 | Design Thinking for innovation management The purpose of this paper is to study the adoption of Design Thinking methods for multi-BU and B2B2C context. Design Theories are used to track generativity of the design practice: user fixation and learning metabolism supporting innovation management. Presented at 6th Creativity Innovation Management (CIM) Community Workshop, first submitted and rejected Spring 2017 to CIM Journal, reformulated for R&D Management Conference 2018 and resubmitted to CIM journal with substantial modifications compared to first version. |

Airbus Development Team Case 1: Waste Management (6 months) Case 2: Turn Around Time (8 months) interviews for each case, field notes and full access to project documentation. |

| 2 | Decision-making in exploration project management In this article directly submitted to CERN IdeaSquare Journal of Experimental Innovation (2017), after a round of reviews for ICED 2017, we presented an exploration project conducted over more than a decade. It showcases the project’s timeline and what could be considered as an irrational due to a preference reversal. We propose instead to extend the notion of rationality with the existence of generative actions and the deliberate will to reverse preferences. These are seen as means to manage the unknown. Departing from optimization, design and generative processes can support this extension and exploration. We consequently introduce the notion decisional ambidexterity. |

Zodiac Fuel and Control Systems Case: Icing conditions detection system (one decade, and additional background history) interviewees consulted several times, field notes and full access to project documentation |

| 3 | Organizational Ambidexterity and innovation management This paper addresses the hypothesis that organizational ambidexterity (OA) can kill innovation. The first version called for the importance of decision-making to understand the operationalization of OA as mentioned by researchers in the field. We propose to leverage non-expected utility decision-making based on Paper 2, but in reality with the feedback from the research community we also recentred the presentation on problem-solving as originally discussed by James March seminal paper (March 1991). We stress the aporia of segregating exploration from exploitation for a meaningful exploration as generativity is otherwise biased and reduced. The latter revealed being crucial to manage the unknown and consequently to innovate. Presented at EURAM 2018 Conference Innovation SIG and will be rewritten based on valuable collected feedback. |

Airbus Development Team and Zodiac Seats France Case 1: Waste Management (6 months) Case 2: Business Class Seat Platform interviews for case 1 and 10 interviews, in addition to field notes, full access to projects documentation. |

Modelling and intervention - Case studies and written papers

| Paper no. | Associated Paper | Associated cases |

|---|---|---|

| 4 | Designing decision: managing the unknown This article discusses the need to overcome the decision paradigm by embracing design theories to extend the latter to the unknown. Four archetypes of decisions based on design paths are presented corresponding to different forms of collective action: learning, performance and organization. Compared to the published paper, we extend the model with organizational theories by integrating organizational constraints and hypothesis in the decision design reasoning to generate and execute alternatives/decisions to be managed in exploration/exploitation modes. Presented on several occasions by Pascal Le Masson, debated with the researcher over the PhD’s second year. After a first round of reviews, a modified version is in press in the European Management Review. |

Theoretical paper The traditional thought experiment of the decision to go out with an umbrella/hat given the weather belief is used. |

| Paper no. | Associated Paper | Associated cases |

|---|---|---|

| 5 | Ambidextrous decisions and corporate entrepreneurship Given the anomaly and the proposed model, we will present two cases that can explain their success and failure. These have a corporate entrepreneurship taste and present features relating to decisional ambidexterity, managing the unknown and organizing for it. One case appears to have the right set of practices to succeed in its innovative design and associated management whereas the other one struggles. The comparison allows justifying the usefulness of the new model and ways to implement certain practices. It is a working paper to be submitted by the end of 2018 to conferences (to be determined) |

Airbus Development Team, Connected Cabin and Multi-BU committee Case 1: Aircraft’s lower deck (1 year) Case 2: Connected cabin (10 months) Field notes, minutes of meetings, 6 interviewees each consulted on multiple occasions and full access to projects documentations, meeting minutes, in addition to input from former CEO and VP. |

Chapter synthesis

After having globally presented the general research methodology of the PhD journey for the research questions refined over the last three years, we have described in this chapter the actual research context.

The history of the aviation industry, its emergence, and its gradual organization and segmentation with the numerous original actors explain the dynamics of today’s market and positioning of players such as Zodiac Aerospace.

This firm has developed specific innovation capabilities through several decades of acquisitions, extending its market footprint. In the last decade, we presented how centralization and gradual homogenization, new coordination means and collective action patterns emerged to cope with the unknown to be managed for future aircraft programs and markets. We exposed also the difficulties for top/middle/local management to address the challenges imposed by exploration project management with respect to the underlying organization designs and market segmentation.

Finally, we introduced the case studies conducted at Zodiac Aerospace and how these led to published and presented articles in journals and conferences. These papers fit with the methodology of anomaly detection, theoretical modelling and empirical testing. We explain how the other cases support the researcher’s intervention, testing and experimentation.

References

Ader, Clément. 1907. La première étape de l’aviation militaire en France. Paris: J. Bosc et Cie. http://cnum.cnam.fr/CGI/redir.cgi?A890.

Barr, Vilma. 1992. “Alexandre Gustave Eiffel: a towering engineering genius.” Mechanical Engineering 114 (2): 58–65.

Carlgren, Lisa, Ingo Rauth, and Maria Elmquist. 2016. “Framing Design Thinking: The Concept in Idea and Enactment.” Creativity and Innovation Management 25 (1): 38–57. https://doi.org/10.1111/caim.12153.

Gallant, Joseph. 2002. “The shape of the Eiffel Tower.” American Journal of Physics 70 (2): 160–62. https://doi.org/10.1119/1.1417530.

Henderson, Rebecca M., and Kim B. Clark. 1990. “Architectural Innovation: The Reconfiguration of Existing Product Technologies and the Failure of Established Firms.” Administrative Science Quarterly 35 (1): 9–30. https://doi.org/10.2307/2393549.

Hölzle, Katharina. 2010. “Designing and implementing a career path for project managers.” International Journal of Project Management 28 (8): 779–86. https://doi.org/10.1016/j.ijproman.2010.05.004.

March, James G. 1991. “Exploration and exploitation in organizational learning.” Organization Science 2: 71–87.

-

see his treatise On Aerial Navigation, 1810 ↩︎

-

Ecole d’Avionnerie: see for instance the letters exchanged between Clémenter Ader and Generals Billot and Laurent in (Ader 1907) ↩︎

-

For more details, see the history written by Claude Rosetti: https://www.isae-supaero.fr/fr/isae-supaero/Institut/hisis-l-histoire-illustree-de-nos-ecoles ↩︎

-

First flight with animals in front of the court of Louis XVI in Versailles on 19 September 1783; and first manned flight with Jean-François Pilâtre de Rozier on 21 November 1783 over Paris by the Castle of La Muette for the crown prince: Louis XVII ↩︎

-

We must specify here that in 1909, Maurice Mallet et al. developed a standard biplane that flew over 70km on December 9, ten months after Blériot XI crossed the English channel (approx. 40km) ↩︎

-

One could even refer to the novel of Jules Verne The Mysterious Island where the characters escape from the siege of Richmond, Virginia with an air balloon. ↩︎

-

http://grundmanadvisory.com/?news=aviation-week-published-grundman-opinion-a-map-of-aerospace-mergers-and-acquisitions ↩︎

-

Definition: the capability of an aircraft to operate safely with respect to its crew, its passengers, on-board goods and outside environment (air traffic and other people including on-ground). ↩︎

-

Note: The reader should not consider that there are different levels of criticality but rather that in order to ease the development, qualification and certification, some equipment are not necessarily queued in the qualification process of the aircraft but as interdependencies are mastered in the integrating aircrafts the certification process can be carried “separately” even though several features are still adjusted through changes requested/submitted between manufacturer and supplier. ↩︎

-

replacing traditional manual mechanical flight controls ↩︎

-

See for instance the experiment lead by Airbus $A^3$ in California to test their modular cabin concept for refurbished freight aircrafts called Transpose ↩︎

-

Hence, the genericization of the Zodiac trademark, rubber coated fabric inflatable boats made also famous by military boats and the Atlantic ocean crossing of Alain Bombard ↩︎

-

former CEO from 2007 to 2017 who more than doubled the revenues and tripled the stock price ↩︎

-

British Owner Sells Weber Aircraft for 85 Million, LA Times, 1992, 7th October ↩︎

-

Note: this career path implied a more traditional management of teams until reaching managing director and escalating the hierarchical line. The project and program management was at first outlined as a comparison (Hölzle 2010) but never formalized by Human Resources. Several cross-overs would occur between programs and traditional management. The projectification of business units would somehow blur their differences despite sustaining the importance of both functions and projects in the matrix. ↩︎

-

Translated by the author: “C’est un levier majeur de croissance pour un Groupe comme le nôtre qui conçoit et réalise les systèmes les plus complexes et qui doit répondre à des contraintes réglementaires et à des exigences de qualité et de sécurité toujours plus fortes. En 2010, nous avons créé le ZSTC pour améliorer l’efficacité de notre recherche technologique, disposer des ressources nécessaires à notre compétitivité, favoriser le développement d’innovations croisées à forte valeur ajoutée.” ↩︎

-

Open interviews conducted by the author in May/June 2018 ↩︎