Chapter 12 - Validation by peers: quality management system contributions

The heart of a good work is a puzzle and an idea. Andrew Abbott

In the previous chapters, we have given further proof of the usefulness of a model of mutual causality between exploration and exploitation: decisional ambidexterity. The role of decision-designers and the technology of organizing are sustained by interactions with the decision-design in the unknown, mapping, categorizing oriented towards by interdependencies and fixation effects. We have also sketched by contrast the usefulness of having an engineering-oriented approach to it: considering methodological approaches and objects to effectively organize collective action.

We present in this chapter several other contributions of the researcher to adapt process management and existing R&T and Innovation practices in Zodiac Aerospace. The initiative was part of a global program on Quality Management System and for Operational Excellence following issues encountered by a few BUs. The CTO was the process leader for Design & Develop, a key process for Program Management. He fought to have an Innovate process, which finally was allocated by the Chief Operations Officer despite not being directly linked with operations in the short term.

It was an occasion to reinforce the value of innovation practices as potential contributor and enhancer to operational issues. In other words, we can think that operational issues faced in manufacturing engineering and quality engineering, can be rooted in design choices. This processual view can then be seen as an occasion to work around the mutual causality between exploration and exploitation, instead of only separating an innovation process and management as a totally isolated regime compared to other organizational concerns.

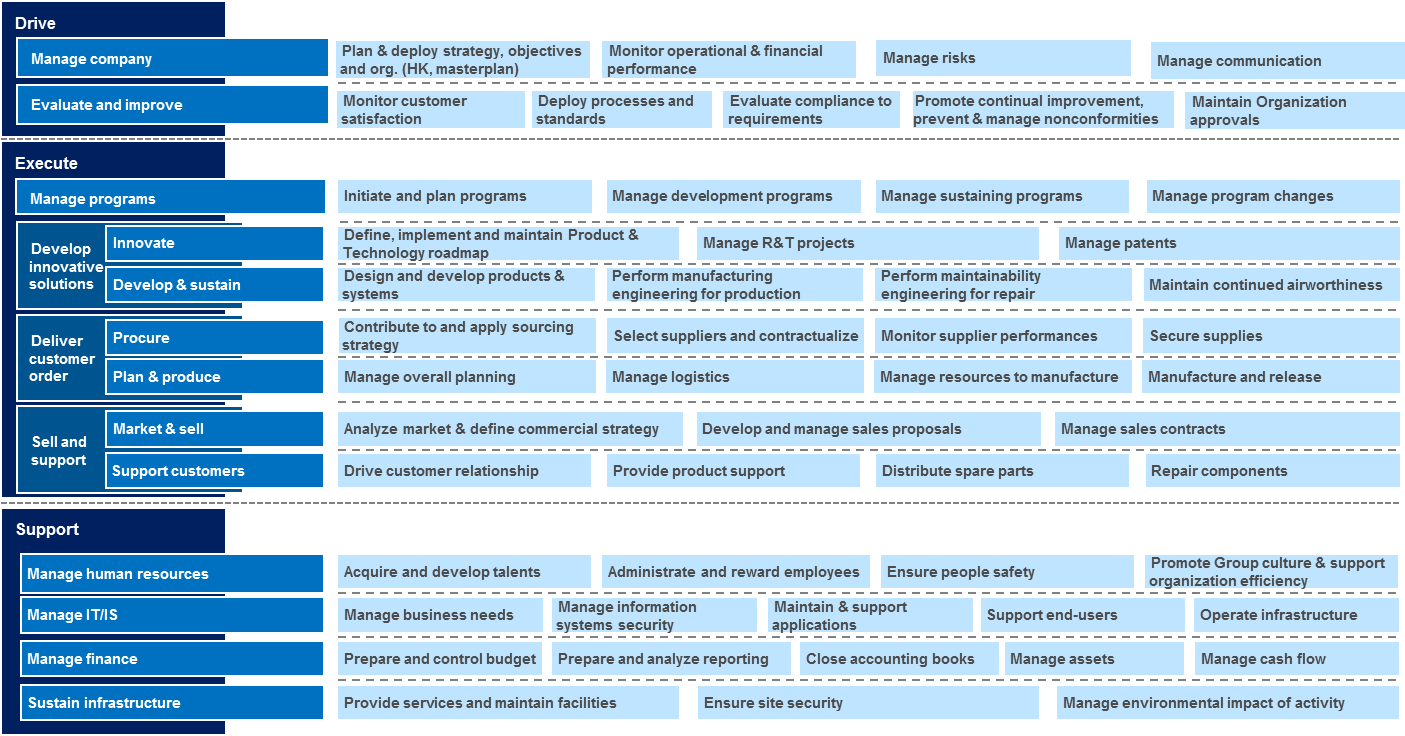

The diagram below (Fig.1) gives a global picture of the 3 main pillars (Drive, Execute, and Support).

In the first section, we start by presenting the procedures written for the ZAOS with the researcher’s contributions. They cover the Design & Develop and Innovate processes. The first defines a traditional new product development, a representation of an exploitation regime, with a strong influence from the optimization of project management. The second process is then seen as upstream, and the researcher tried to distil it in the model of decisional ambidexterity.

Then, we discuss the feedback gained from several R&T managers community workshops where the procedures were reviewed and where the researcher had the occasion to discuss his model of decisional ambidexterity. Similarly to the ZAOS procedures, these contributions show the issues of surfacing an organizational metabolism against the duality of processes and structure.

Group procedures: Design & Develop and Innovate

Following some quality and delay issues, corporate teams had launched programs of operational excellence across the group. Originally, it was formalized in key requirements for operations (supply chain, manufacturing, industrialization, customer management). Later, it was formalized into an update of the quality management system to prescribe a set of key principles and procedures. The movement initiated for critical process then moved “upstream” to tackle Design & Develop and Innovate.

The researcher had first participated to the Program Management procedures writing to identify how R&T activities could be articulated (TRL assessment for risk management, technology acquisition and integration and multi-BU projects). Then, an even more active contribution was made to Design & Develop. It was an occasion to contribute and gain sufficient knowledge on exploitation regime. Consequently, it helped formulate proposals for management devices instilled by decisional ambidexterity in Innovate procedures.

We present the linear view of designing and developing products in the ZAOS. It is part of a more global processual perspective of the exploitation regime that tries to avoid referring to organization structures. Innovation is then placed as an upstream process, we discuss its interface and assumptions.

Then, we show the Innovate procedure and how the researcher tried accommodating decisional ambidexterity by introducing the governance construct for road-mapping activities.

Design & Development procedures

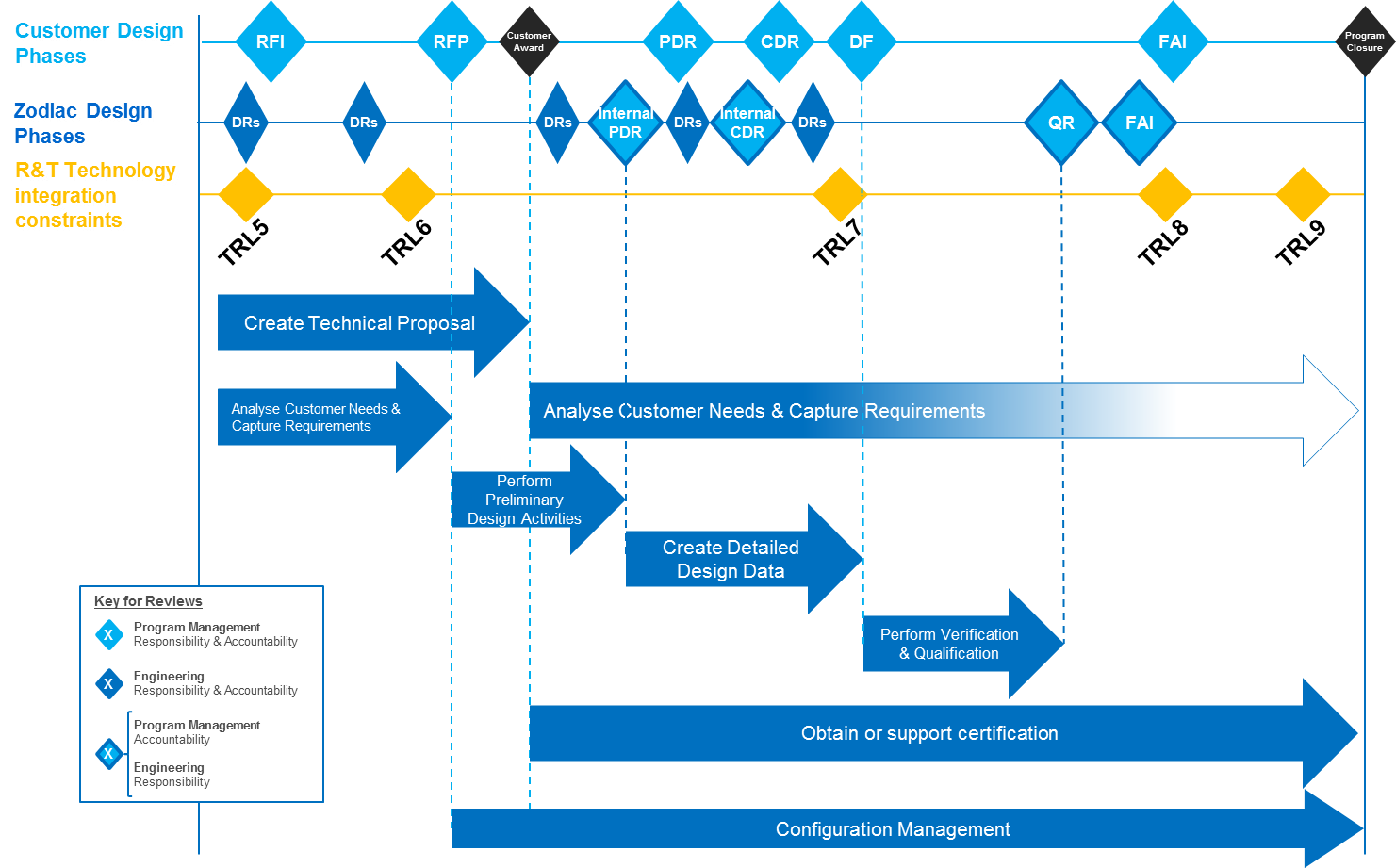

In the figure below, we present the overall process of Develop & Sustain with inputs/outputs from other processes, as well as suppliers and customers of different processes: Design & Develop, Perform industrialization, Perform maintainability engineering for repair, and Maintain continued airworthiness.

The overall perspective of designing and developing makes several assumptions on the linearity of the process. Customer have need, voiced to the business unit through bidding teams and programs framing the undertaking waterfalled to different underlying processes (see figure.1). As we see below in Figure.2, the suppliers/customers in bold purple letters are other processes providing and expecting actions and deliverables (note: circular references are possible because of iterations).

Given several inputs and interactions with other processes, responsibility, accountability, support, consultation and information are distributed among functional activities (jobs), with some overlap, interactions but with a global movement forward, the sub-processes are the following:

-

Create Technical Proposal

-

Analyse Customer Needs & Capture Requirements

-

Perform Preliminary Design Analysis

-

Create Detailed Design Data

-

Perform Verification and Qualification

-

Obtain or Support Certification

-

Configuration Management

This exploitation regime is heavily dependent on the client’s demand and makes the assumption the client knows to some extent how to formulate requirements to a congruent business unit (bidding and engineering team) capable to discuss and support in the formulation of engineering specifications and rules to conduct product development.

Numerous debates during writing workshops (for program management, develop & sustain, as well as innovation) took place because of differences in organization design. The struggle was hard to adopt the view of the quality management system which enforces a strong processual view. The process should be high-level enough to be transposable between business units. The compromise found to avoid specificities was to add some depth to the processes for organizations to better identify with maturity matrices.

Project-based management principles

Project management principles are induced by the framing and management of overarching programs. They impose the breakdown of the activities in work packages supported by team. Resources are picked among whatever organization is in place following the matrix-form (Galbraith 1971).

Resources are allocated depending on customer requirements and derived specifications. What is rather surprising in the writing of these activities and responsibilities is the implicit reference to the necessary competencies and capabilities to continuously be able to develop new products and cope with adaptation to change

R&T and Innovation interface

As we can see in the previous figure, they have linearized the R&T activities, through the TRL assessment (Mankins 2009). It corresponds to a stage-gate equivalent (Cooper 2007). Of course, such linear and adaptive view is more appropriate for incremental innovation. Product development and engineering refers to a pool of technologies capable of being integrated as the TRL freezes the integration environment to measure the technology maturation. So, if the engineering rules for products remain stable enough and that these are made clear, it can be considered that maturity assessment will filter and perhaps bring adjustments to technologies.

Consequently, when it comes to major innovations initiatives, they would originate from another process that necessarily challenges or even by-passes traditional adaptive and maturation processes. From the researcher’s viewpoint and as discussed on multiple occasions with the CTO, the quality management system had to sanctuarise these processes in Innovate. Indeed, Design & Develop restricts its scope to a traditional exploitation regime with its lot of hypotheses on nature of risks, certainties, fixations and marginal correction of biases & heuristics.

The structure of the ZAOS, with the cross-referencing of processes of different nature, forces to build coherence between them as well as delimiting their perimeter. The scope and the risk of leaving activities unmanaged was taken care of by the ZAOS project team. On some occasions, it was also circumvented by using maturity matrices to provide additional detail on how activities can be conducted with underlying competencies and capabilities.

Overall, Design & Develop describes the exploitation regime fed by some optimizations that can be decided as they improve product design & development with technologies capable of being integrated.

From the decisional ambidexterity perspective, it provides enough ground to envision designing decisions capable of changing products, their development and required capability. Since, we face a traditional model of ambidexterity, decisional ambidexterity model is bound to be upstream but encourage to disentangle fixations effects and interdependencies.

Innovate procedures

The Innovate process was the last in being written in the ZAOS program. Some place had been made already for incremental innovation with more traditional R&T activities focusing on technology maturation made available to product development and program management.

A preliminary round between the CTO, his North America delegate, the Intellectual Property director, and the PhD Candidate was organized to provide an overall framing. This original draft helped giving some directions to the writing workshop participants. The main issue was defining whether or not the process should consider product design and innovation, in addition to technologies. And more common to other processes in the ZAOS, sub-processes and topics were reallocated and articulated differently under the umbrella of the agreed main processes after several iterations:

-

Define, Implement and Maintain Product & Technology Road maps

-

Manage Research & Technology Projects

-

Manage patents and create patent landscape

Innovate complements what exploitation doesn’t cover. In other words, it feeds exploration regime. It is regarded upstream to provide technologies to improve continuously product along its roadmap. However, the group quickly insisted on approaching the subject with additional processes catching other forms of innovation. It was necessary due to the variety of products, sometimes relying on several common technologies (material, composite, flammability, electronics, EMI, etc.), and due to the value of design and layouts for cabin and seats equipment.

Consequently, the working group had to precise the articulation of other innovation streams and practices contributing to exploration and differing from the linear, continuous and adaptive view of innovation.

As we show, in the following paragraphs, decisional ambidexterity explains the nature of these innovation streams contributing in more complex ways and differing from traditional models of ambidexterity.

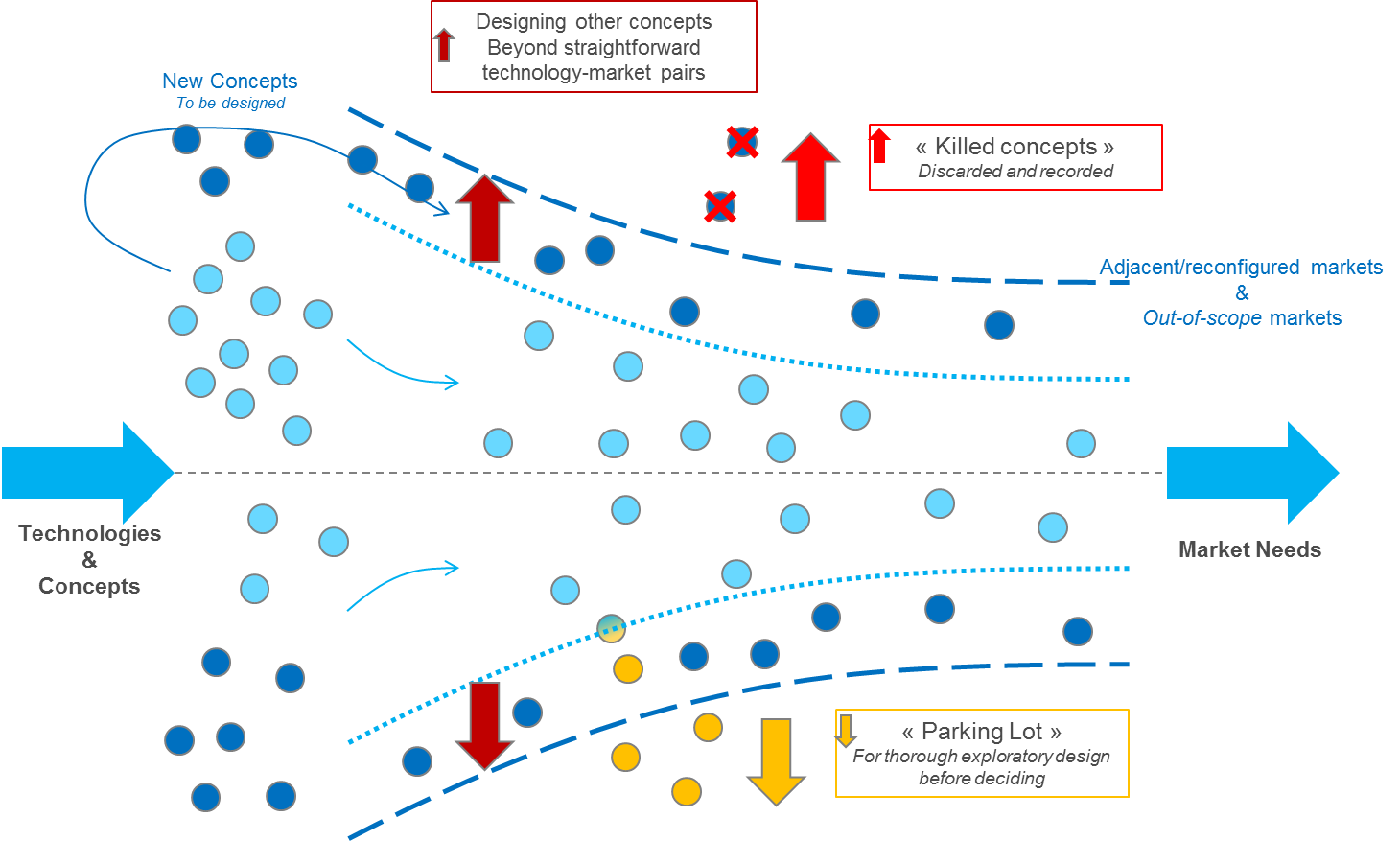

Revisiting the innovation funnel

In order to provide a basis for discussion, the researcher used traditional ways of representing innovation. The famous funnel implies uncertainty reduction through a stage-gated with an hypothetical target and environment. It is rather fixated. He then proposed to use its parameters and assumptions to show that other innovations, differing from technology maturation could be considered:

-

Technologies and Products can be created but do not have yet a market

-

Markets can be created but do not have yet a product or technology

These two simple statements encourage after defining what the funnel is1, to envision other scenarios and concepts to be decided. The figure 5 below incites to revisit the innovation funnel, not only to show the necessary feedback loops between gates to reach an a priori defined target, but also to show the porosity of the funnel and its elasticity/plasticity as new decisions rule its scope and curvature.

The colour code identifies different types of concepts relying on a specific decision-making. The light blue refer to technologies and (design) concepts that can fit the environment and adjust with existing engineering design rules.

Dark blue is for new concepts that tend to modify the shape of the funnel. Some can be fully discarded (red-cross) because they are decided to be out of scope, e.g. they require escalating decision and involve strategic discussions challenging the overall model of business or firm’s identity.

Others may be left in a parking lot (yellow) as the decision requires deeper value management to understand how to generate a future fit with organizations: e.g. the lower deck project.

Otherwise, the dark blue concepts may require to search or support suppliers in developing technologies, or inversely searching or co-innovating with customers and users to shape the future market. The Icing Conditions Detection project revealed several features of this interplay between technology and market design.

Decision-design and Innovation governance

Introducing such interactions touching upon organizational metabolism, the writing team had to provide a means to manage such decisions. They relied on existing practices, i.e. road mapping activities for technologies and products.

First, the group included the product road map as part of Innovate whereas in the past it was absent and only focused on technologies (R&T). It allowed to be more representative of less business units who focus rather on design features (cabin and seats), besides common topics such as materials.

Secondly, the main issue raised by writing workshop participants was the handover between innovation teams and product development and sales/marketing. The issue was not the handover dossier nor technical items, but rather to have some buy-in from them. Moreover, enforcing a top-down was not necessarily the solution according to participants’ experiences.

With the CTO, they proposed to introduce a governance body to orchestrate the alignment and change of roadmaps for technologies and products. The American colleague (CTO’s delegate for the Americas) was not very comfortable with it as it has a stronger meaning than in France (more related to the firm’s Board). Nevertheless, due to the weight and twist they wanted to give to this management of decisions and concepts, they kept it. The procedure asks to organize meetings with BU stakeholders, invited experts from the group (if relevant), and the group CTO. Interactions in meetings are encouraged then to discuss what can change for the funnel and in between roadmaps. The point is to discuss what makes decision and position concepts accordingly. Experts can bring additional knowledge. And the CTO can spot opportunities outside of the BU, or find connections for multi-BU projects.

In other words, we insisted on the innovation potential of attraction, resurfacing rules for decisions on product engineering and development, in order to fit to them or redesign them with according knowledge and organizational change. The word metabolism wasn’t used but the interactions and the management device through this governance body is here to support such phenomenon.

The Innovate process defined as complement to the exploitation regime in Design & Develop offers a first to reconsider a reductive model of ambidexterity for R&T activities and articulate other innovation streams. Decisional ambidexterity is used to condition exploration by exploitation parameters and constraints usually represented through a funnel.

Given the obstacles reported by R&T managers and innovation practitioners, they proposed to work on the articulation of their activities with exploitation regime. Bringing interactions and managing them around fixations effects and interdependencies through the lens of decisional ambidexterity, allows to propose new means of actions for existing objects such as road maps. The decision design is distilled in the process and embodied by governance of roadmaps during meetings.

Approach and validation with R&T Managers

Former Aérazur group of business units had their own quality management system and shared common practices as well similar technologies (fabric, composite material, injection moulding). When the R&T activities had been gradually established in 2013, they had set up an exchange group with the recently appointed R&T managers. In late 2016, after a year without meetings, the group was set up again, and enlarged to other business units in France, i.e. not restricted to former Aérazur. The researcher was already known to these managers, had worked with them on their management practice, and had consulted them to collect input for innovation procedures update (before and during ZAOS project). They held five meetings between 2017 and 2018 to discuss several topics:

-

Key Performance Indicators for R&T management

-

Handover between R&T and other BU stakeholders

-

Expertise and technologies knowledge access across BUs

-

Decision-making and design practices for R&T and advanced concepts

The agenda was set by the main organizer and the researcher. The group was consulted beforehand to adjust according to their interests and were requested to present their perspective on agenda’s topics.

Below, we share feedbacks collected through the five workshops organized by the R&T managers community. The researcher consulted this group of people outside the procedure writing workshops.

The researcher tested also how decisional ambidexterity could be adapted to the process management perspective of the new quality management system in addition to complementary methods and practices.

Rethinking evaluation of concepts

Several projects hosted in BU’s respective R&T departments struggled to beyond TRL6, i.e. the gate beyond which the Product Development engineering should take over. All BUs had a history of numerous product innovation, technology development, and most had been successful before delimiting an up-stream activity (R&T, Innovation or Advanced Concepts). Of course, many other projects had failed or led to high risks taking when developing products for clients.

As we have stressed earlier, TRL assessments consider environment being fixed, so entering the evaluation is made for a given target with its integration assumptions. Several discussions were oriented on how the environment could be shaped to create a generative fit, as they agreed it couldn’t be so deterministic for some technologies and products.

Following three meetings, one of the R&T managers reported he had several TRL6 technologies waiting to handover to product development and industrialisation. He had organized several meetings with stakeholders, but industrialisation and operations wouldn’t show up; after several attempts, projects went further with the support of a salesman. Such initiatives led to tensions between departments despite having verbal and signed agreement following the organized meetings (email and signing sheets).

Consequently, he proposed to create an interface for such meetings. The idea of having management device to channel interactions was acknowledged crucial. They made the parallel with brainstormings without a proper coach: rules and isolated brainwriting give voice to all ideas. An Excel spreadsheet was formalised to decide on concepts interest. Criteria were defined and given a weight by BU stakeholders. The objective was first to decide on the interest and value of concepts.

However, the second underlying objective was to envision the possibility of reviewing some criteria (with a poor value or ranking) in order to identify what had to change in the BU to enable the decision: engineering rules, client relationship, use cases, suppliers, technical feasibility, manufacturability, etc.

They managed to emphasize the cruciality of discussing what makes decisions for R&T and innovation concepts to better work out the articulation with exploitation regime.

Paradoxically, decisional ambidexterity applied heuristics developed during the meetings allowed reconnecting innovation streams with the gaps created by traditional models of ambidexterity.

The augmented Proof of Concept

During one of the meetings, they also took the opportunity to discuss the Hypoxia Protection project. The several practices of opening the project were presented such as discussing digital and physical mock-ups with stakeholders.

The point was to try to test the idea of revisiting the traditional proof of concept as defined in a TRL assessment. A prototype presented to stakeholders to check pre-defined criteria could lead to a standstill. So, they debated over how they could discuss the evolution of criteria thus enabling other concepts.

To do so, the researcher proposed to work on what an engineering model is. He took an external example (aircraft engine) which can be described with simple equations at a certain order in functional analysis. He insisted on specifying assumptions and impacts on engineering rules, interfaces between sub-systems and organization mirroring. Consequently, they could discuss how simple variations on equation parameters could radically engineering rules and organization. For instance, one can shift from a turbojet to a turbofan by playing on inlet cross section, and shift even to open rotor turbofans by making the cross section infinite. The first shift has a strong impact on mechanical gear and shaft system. The second shift changes the physics altogether, since part of the engine is unducted, so propellers’ equations have to be integrated. Such simple tricks in the model handling ripple out through an engineering organization as well as for an entire business unit and environment.

“What If?” to articulate strategic intent and organization design

Finally, the researcher discussed hacking to value emergent strategies. One R&T manager was very receptive and presented us his way of designing his strategy. His business unit has been facing market share losses and difficulties in opening new markets because of lowering entry barriers (known technology) and regulations.

New growth opportunities had to be found and these would be out of the aircraft industry. Sticking to the history of technology transfers and genericity to different systems integration, he developed alternatives. The methodology formalizing technology roadmaps definition and creation was used to identify hackable parameters. Indeed, he acknowledged presenting to his managing directors highly uncertain Net Present Value calculations and business models. However, his presentations aimed at showing how they could become true or less uncertain by identifying means of action to uncover the share of unknown. Another representative from another BU, shared a history of business plans requested by his local financial director who systematically requested them. He used these models to show the absurdity of such planning per se, and twisted to identify what had to be redesigned internally or in the environment to enable the business cases.

The meeting’s participants acknowledged such practices. In some way or another, they had performed similar hacking in their own fashion and with variations. For instance, one relied on formalized business plans for his financial director not only to “cheat” and gain his approval, but also to point at where the effort should be put to make these cases come true. As for the previous modelling effort for engineering and organizing, they stressed the difficulty in transposing across BUs. The R&T managers were more keen in having a set of heuristics and method to adapt and apply them to their specific practice.

There is no one best way so it encouraged the researcher to find generic enough. We didn’t take the time to introduce decisional ambidexterity as it has been formalized here in the thesis’ manuscript or in our publication.

The meetings held with R&T managers from the French BUs were rich in debate to discuss management issues. During these meetings and the evolving agendas, we tried to test some declinations of decisional ambidexterity before its actual formalization.

We see that they came with their own practices and tricks to overcome limitations of traditional models of ambidexterity. However, they report on the difficulties to have a systematic way of playing on fixations effects and interdependencies to value their project’s portfolio. In other words, it encourages to work on a baseline that would help them to reconciliate the tensions between the models organizational ambidexterity and exploration projects.

Chapter synthesis: decisional ambidexterity enhancing process management

In this chapter, we have presented how the researcher contributed to the quality management system through the Design & Develop and Innovate processes. We tried to accommodate decisional ambidexterity within the processual perspective and it reveals some difficulties circumvented by the introduction of the notion of governance for road-mapping activities.

The discussions during workshops with the R&T managers from French BUs reveal also the complexity for them to implement approaches extending limitations of traditional models of ambidexterity. They recognize the results of the thesis, they identify with patterns of decisional ambidexterity, but still struggle to implement or develop their own technology of organizing. The disentanglement of fixations effects and interdependencies is complex and perhaps even chaotic. However, the interactive meetings proposed in the procedure to discuss and design decisions opened some possibilities, as some colleagues had implemented similar practices or were about to.

Our work trying to collect and propose means of formalizing decisional ambidexterity is not finished despite having tested ideas of implementation. The logics appear quite normal to them, as it was also recognized by the former CEO and discussed for the Multi-BU committee.

This chapter closes our work at Zodiac Aerospace and our testing of the decisional ambidexterity supporting its validation as an extension of models of ambidexterity. As shown here, it provides means of action to avoid the limitations we had extensively discussed in previous chapters when starting the PhD journey. The following chapters will discuss what we have achieved so far before concluding this thesis.

References

Cooper, By Robert G. 2007. “Managing Technology Development Projects.” Stage-Gate 35 (1): 67–76.

Galbraith, Jay R. 1971. “Matrix organization designs How to combine functional and project forms.” Business Horizons 14 (1): 29–40. https://doi.org/10.1016/0007-6813(71)90037-1.

Mankins, John C. 2009. “Technology readiness assessments: A retrospective.” Acta Astronautica 65 (9): 1216–23.

-

what the box is, to think out of it and it in comparison to ↩︎